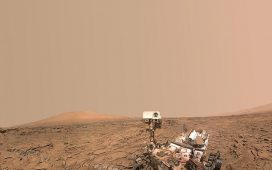

Spaceships heading to Mars could serve its crew three-year-old macaroni and cheese for dinner.

Scientists have developed a new technique that triples its lifespan – keeping food fresh for the brave individuals making the eight month journey to the red planet.

Using microwave assisted thermal sterilization and adding a metal oxide coating to a plastic packaging, the team was able to increase the amount of time it takes for oxygen and other gases to break through.

Scroll down for video

Spaceships heading to Mars could serve its crew three-year-old macaroni and cheese for dinner. Scientists have developed a new technique that triples its lifespan – keeping food fresh for the brave individuals making the eight month journey to the red planet

The new development comes from a team at Washington State University (WSU), who started with a goal to feed astronauts and military personal who cannot make it home for a fresh meal.

As of now, food is kept in regular plastic packaging that keeps it safe at room temperature for no more than 12 months.

But the team has designed a better barrier that can keep oxygen and other gases at bay – and the demonstrated this technique using macaroni and cheese.

‘We need a better barrier to keep oxygen away from the food and provide longer shelf-life similar to aluminum foil and plastic laminate pouches,’ said Shyam Sablani, who is leading the team working to create a better protective film.

‘We’ve always been thinking of developing a product that can go to Mars, but with technology that can also benefit consumers here on Earth.’

To increase the lifespan, food must first be sterilize using what is called the microwave-assisted thermal sterilization (MATS) system, which unique technology from WSU.

And it must be sterilized in plastic, as metal cannot be microwaved and glass is not ideal for spaceships or the military.

The team then added a metal oxide coating to a layer of the plastic film, which is the key step to increasing the amount of time it takes for oxygen and other gases to break through.

The metal oxide coating technology has been around for almost 10 years, but it was found to crack during the sterilization process – resulting in a lowered shelf-life.

However, WSU has been working with packaging companies to develop new films that keep oxygen and vapor out longer.

The packaging films are made up of multiple layers of different plastics that each have their own specific purpose, such as being a good barrier, good for sealing, good mechanical strength, or good for printing, Sablani said.

‘We are excited that an over-layer of organic coating on metal oxide helped protect against microscopic cracks,’ he said.

‘Multiple layers of metal oxide coating have also increased the barrier performance.’

‘Our research guided development of newer high barrier packaging.’

Using microwave assisted thermal sterilization and adding a metal oxide coating to a plastic packaging, the team was able to increase the amount of time it takes for oxygen and other gases to break through

In taste panels conducted by the Army, the macaroni and cheese, tested after three years of storage, was deemed just as good as the previous version that was stored for nine months.

Although it is near impossible to test the food in orbiting spaceships, Sablani has plans to reach out to NASA to test the WSU films in order to make sure that packaged food stays edible on a space mission where failure isn’t an option.

‘NASA knows about our work, but we’re just now getting to the point where we can talk to them with a proven product,’ Sablani said.

‘We hope to work out a way to test these products on the International Space Station in the future to show that the food is safe after long-term storage.’

NASA will require storage of up to five years for food, so that’s what the team is working on now.

They are currently aging other recipes that will be taste tested once they reach the five year mark.

Several types of mission plans have been proposed for a trip to Mars. The five-year food storage includes some built-in safety requirements, Sablani said.

It may involve an approximately nine month travel time from Earth to Mars, about five hundred days on or orbiting Mars, and a travel time of about nine months to return to Earth. The extra storage time is necessary in case the mission is delayed and explorers must stay longer.

In addition to having space travel in mind, the researchers are working closely with the U.S. Army, who want to improve their ‘Meals Ready to Eat’ (MREs) to stay tasty and healthy for three years.

‘If they like the taste of the packaged food there, then that’s the ultimate test of new films,’ Sablani said.

The team doesn’t wait the three years to test the results of each new film. Keeping the packaged food in a 100-degree Fahrenheit incubator rapidly speeds up the food quality changes at a consistent rate. Six months in the incubator is equivalent to three years at room temperature, while nine months is the equivalent to nearly five years, Sablani said.