A computer-controlled machining system is referred to as a CNC machine. They make it possible for manufacturers to automate numerous manual manufacturing processes.

CNC-powered machines, on the other hand, reduce waste, increase productivity, and even eliminate the possibility of human error. Utilizing actuators, drives, and software programs, CNC machines can also produce a variety of products. CNC machines come in many different kinds.

Laser Cutting CNC Machine

A few kinds of laser cutting machines are accessible, ordered into gas, fluid, and strong state lasers. The state of the active laser medium, i.e., distinguishes the types. Whether the medium is a gas, liquid, or solid, and the active laser medium’s composition (for instance, CO2, ND: YAG) CO2 lasers and solid-state lasers are the two main types of lasers utilized.

A CO2 laser uses a mixture of carbon dioxide as the active laser medium, making it one of the most widely utilized gas state lasers. Because the earliest machine models lacked the power to cut through metal, CO2 lasers typically only cut non-metal materials. CO2 lasers are now capable of cutting through metal because of advances in laser technology. CO2 lasers, on the other hand, are still better suited to engraving metals or other hard materials and cutting through organic and non-metal materials. Another common gas state laser is pure nitrogen lasers. Applications that require the material to not oxidize during cutting make use of these lasers.

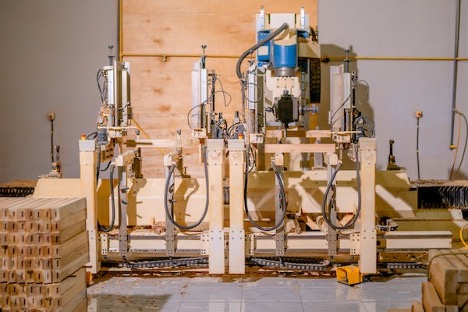

CNC Milling Machine

The workpiece is shaped by milling with a CNC machine using rotating multi-point cutting tools. Processing apparatuses are either evenly or in an upward direction situated, including end plants, helical factories, and chamfer factories.

Additionally, CNC-enabled milling machinery, also known as mill machines or mills, which can be oriented either horizontally or vertically, are utilized in the CNC milling procedure. Basic mills can move on three axes, while more advanced models can move on more axes. On our website, you can also get CNC freesmachine voor hout for your woodworking process.

Plasma Cutting CNC Machine

Materials are cut with plasma cutting CNC machines. They cut through their materials with a plasma torch. The fundamental condition for CNC plasma cutting machines is that the material or workpiece to be cut should be electrically conductive. Brass, copper, aluminium, steel, and stainless steel are some common materials utilized in plasma cutting.

A powerful torch on a CNC plasma cutting machine can cut through steel and titanium, two of the hardest materials. Using a nozzle and high-velocity gas, a CNC plasma cutting machine creates a powerful torch.

At the point when the light is made, an electric circular segment is delivered. The plasma, an electronically ionized gas, forms as the arc passes through the high-velocity gas and jumps onto the cutting material.

How to Choose the Best CNC Machine Type

The best CNC machine type is determined by the CNC process and working materials you intend to employ. The machine’s weight, work radius, speed, availability of spare parts, and power consumption are important factors to take into account.

The normal materials utilized in building CNC machines are wood, aluminum, polymer composite, and iron cast. When you need a machine that will stand up to tough jobs, the iron cast is the best build. For simpler tasks, you can use other materials.

Your CNC machine should be bigger than your products’ maximum surface area. The radius of your machine must be larger than the largest material you cut. When choosing the best CNC machine type, it would be helpful to take into account the feed rate. During the manufacturing process, it determines the rate at which materials can be cut.

A CNC machine, like any other appliance, can break down or become worn out over time. You should make sure that the brand you buy can be easily fixed by your technicians and that spare parts are available. Reduced downtime will result from this.

The workshop’s power may need to be increased depending on the machine you choose. It is essential to check your machine’s power requirements and make any necessary adjustments at work.