California farming startup begins selling vegetables grown by a ROBOT (and they cost about as much as you’d spend at Whole Foods)

- Iron Ox will sell its robot-grown greens to the public for the first time

- The system uses a robot arm, an automated porter, and an AI computer system

- Robotic farming promises to reduce footprint and increase yield

- The use of automated tech in farming could be crucial for future food supplies

Vegetables sold by California-based startup Iron Ox might be organic, but the farmer cultivating them is far from it.

The company behind the robotic and hydroponic farming system is now taking the first step towards going to market in California.

According to a report from The Verge, Iron Ox is partnering with Bay Area produce purveyors Bianchini’s Market, to put several varieties of its robot-grown leaf greens on shelves for the first time.

For now, Iron Ox’s greens will come in the three different varieties: red-veined sorrel, Genevieve basil, and baby lettuce, at prices that are competitive with those at shoppers’ average Whole Foods.

Scroll down for video

Iron Ox will begin selling its robot-farmed produce in California for the first time. The startup is partnering with Bianchini Market

The company’s robotic farms use a chorus of automated tools to bring their produce to life that include a 1,000 pound porter used to cart pallets of seedlings, a robotic arm that is capable of picking and planting seedlings, and a computer system named ‘the brain’ that provides the automated instructions for the farming process.

Among the advantages of its robotic systems, says Iron Ox, is the ability to offer fresh and organic produce at a reduced footprint.

According to The Verge, Iron Ox says that because of its compact operations, lettuce sold at Bianchini’s will travel just 0.6 miles to get to the store, which compared to the average distance traveled by a head of lettuce is about half the distance.

This could also create a number of benefits from, both from an environmental standpoint by reducing the amount of fossil fuels used in transporting produce and from a cost perspective — fewer miles means less money spent.

Being able to buy Iron Ox’s produce on shelves marks a major step not only for the startup, but for a growing sector of robotic farming companies who are looking to revolutionize the industry.

According to Iron Ox, their system is capable of delivering about 30 percent more produce per acre than a regular farm.

As the human population continues to expand and a changing climate threatens food production, the efficiency and production of farms will likely only become more critical.

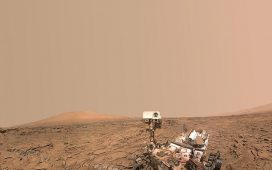

A team made up of a robot arm, an automated porter, and AI are behind Iron Ox’s system, seen above

‘What will a farm look like in 50 to 100 years?’ David Slaughter, a professor of biological and environmental engineering at UC Davis told Engineering.com.

‘We have to address population growth, climate change and labor issues, and that has brought a lot of interest to technology.’

This process will likely involve a constellation of technologies like automated tractors, unnamed aerial vehicles, and smart irrigation systems. One $36,000 Japanese drone is capable of spraying a field with pesticides in just 15 minutes which is a quarter of the time a human needs.

For now, however, even the automated systems will required some human input.

According to Iron Ox, while robots tend to the planets during the growing process, humans are still required to pick and plant the produce.